PID regulation and basic principle

The current level of industrial automation has become an important indicator of the level of modernization in all walks of life. At the same time, the development of control theory also experienced three stages: classical control theory, modern control theory, and intelligent control theory.

Typical examples of intelligent controls are fuzzy automatic washing machines. Automatic control systems can be divided into open-loop control systems and closed-loop control systems. A control system includes controllers, sensors, transmitters, actuators, input and output interfaces. The output of the controller is added to the controlled system through the output interface and actuator, and the controlled volume of the control system is sent to the controller via the input interface via sensors and transmitters. Different control systems have different sensors, transmitters, and actuators. For example, pressure control systems use pressure sensors. The sensor of the electric heating control system is a temperature sensor.

At present, there are many PID controllers and their controllers or intelligent PID controllers (instruments). The products have been widely used in engineering practice. There are various PID controller products. All major companies have developed PIDs. The intelligent regulator of the parameter self-tuning function, in which the automatic adjustment of the parameters of the PID controller is realized through intelligent adjustment or self-correction and adaptive algorithms. There are pressure, temperature, flow, level controllers that use PID control, programmable controllers (PLC) that can implement PID control functions, and PC systems that can implement PID control.

Programmable controllers (PLCs) use their closed-loop control modules to implement PID control, while programmable controllers (PLCs) can be directly connected to ControlNet, such as Rockwell's PLC-5. There are also controllers that can implement PID control functions, such as Rockwell's Logix product family, which can be directly connected to ControlNet and use the network to implement its remote control functions.

1, open-loop control system

The open-loop control system means that the output of the controlled object (controlled quantity) has no effect on the output of the controller. In such a control system, it does not rely on sending back the controlled quantity to form any closed loop.

2. Closed-loop control system

A closed-loop control system is characterized in that the output of the controlled object of the system (the controlled variable) is sent back to affect the output of the controller, forming one or more closed loops. The closed-loop control system has positive feedback and negative feedback. If the feedback signal is opposite to the system setpoint signal, it is called negative feedback. If the polarity is the same, it is called positive feedback. Generally, the closed-loop control system uses negative feedback. , also known as negative feedback control system. There are many examples of closed-loop control systems. For example, a human being is a closed-loop control system with negative feedback. The eye is a sensor and acts as a feedback. The human body system can make various correct actions through continuous correction. Without eyes, there is no feedback loop and it becomes an open-loop control system. In another example, when a genuine fully automatic washing machine has the ability to continuously check whether the laundry is washed and can automatically cut off the power after washing, it is a closed-loop control system.

3, step response

The step response is the output of the system when a step function is added to the system. Steady-state error refers to the difference between the expected output and the actual output of the system after the response of the system has entered the steady state. The performance of the control system can be described in terms of stability, accuracy, and speed. Stability refers to the stability of the system. A system must be able to work properly. It must be stable first, and it should be convergent from the point of view of step response. It refers to the accuracy and control accuracy of the control system and is usually stabilized. Steady-state error description, which represents the difference between the steady-state value of the system output and the expected value; fast refers to the rapidity of the response of the control system, and is usually described quantitatively by the rise time.

4, PID control principle and characteristics

In engineering practice, the most widely used regulator control law is proportional, integral, differential control, referred to as PID control, also known as PID regulation. The PID controller has been in existence for nearly 70 years. It is one of the main technologies for industrial control because of its simple structure, good stability, workability, and ease of adjustment. When the structure and parameters of the controlled object cannot be fully grasped or the precise mathematical model cannot be obtained, when the other techniques of the control theory are difficult to use, the structure and parameters of the system controller must be determined based on experience and on-site debugging. The application of PID control technology is the most convenient. That is, when we do not fully understand a system and controlled object, or cannot obtain system parameters through effective measurement methods, it is most suitable to use PID control technology. PID control, actually there are PI and PD control. PID controller is based on the system error, using the proportional, integral, differential calculation of the control of the amount of control.

Proportional (P) control

Proportional control is the simplest type of control. The output of the controller is proportional to the input error signal. When there is only proportional control, there is a Steady-state error in the system output.

Integral (I) Control

In integral control, the output of the controller is proportional to the integral of the input error signal. For an automatic control system, if there is a steady-state error after entering the steady state, the control system is said to have a steady-state error or a system with Steady-state Error. In order to eliminate the steady-state error, an "integral term" must be introduced in the controller. Integral term pair error depends on the time of the integral, as time increases, the integral term will increase. In this way, even if the error is small, the integral term will increase with time. It will push the increase of the output of the controller to further reduce the steady-state error until it reaches zero. Therefore, the proportional + integral (PI) controller can make the system have no steady state error after entering the steady state.

Differential (D) control

In differential control, the output of the controller is proportional to the derivative of the input error signal (ie, the rate of change of the error). The automatic control system may oscillate or even lose stability in overcoming the error adjustment process. The reason is that due to the presence of larger inertial components (links) or delay components, it has the effect of suppressing errors, and the change always lags behind the change of error. The solution is to "lead" the change in the effect of the suppression error, ie when the error is close to zero, the effect of the suppression error should be zero. This means that introducing only the “proportional” term in the controller is often not enough. The proportional term only acts as the magnitude of the amplification error, and what is currently needed to increase is the “differential term”, which can predict the trend of error variation. In this way, a controller with proportional + differential can make the control action of the suppression error equal to zero or even negative in advance, thereby avoiding a serious overshoot of the controlled volume. Therefore, for the controlled object with large inertia or lag, the proportional plus derivative (PD) controller can improve the dynamic characteristics of the system during the adjustment process.

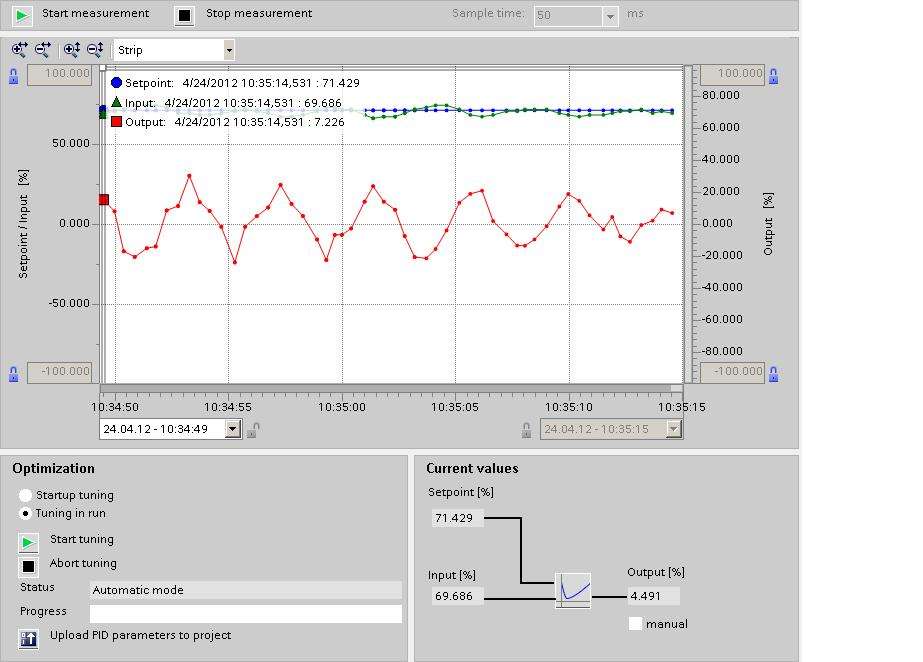

5, PID controller parameter setting

The parameter setting of the PID controller is the core content of the control system design. It is based on the characteristics of the controlled process to determine the size of the PID controller's proportional coefficient, integration time and derivative time. There are many ways to set PID controller parameters. To sum up, there are two major categories: First, the theoretical calculation method. It is mainly based on the system's mathematical model, through the theoretical calculation to determine the controller parameters. The calculation data obtained by this method may not be directly used, but must also be adjusted and modified through actual engineering. The second is the method of engineering setting. It mainly relies on engineering experience and is directly conducted in the test of the control system. The method is simple and easy to master. It is widely used in engineering practice.

The engineering tuning methods for PID controller parameters include critical ratio method, response curve method and attenuation method. Each of the three methods has its own characteristics. Its common point is to pass the test, and then adjust the controller parameters according to the engineering experience formula. However, no matter which method is adopted, the controller parameters need to be adjusted and improved in the actual operation. The critical ratio method is now generally used.

The steps for setting the parameters of the PID controller using this method are as follows: (1) First, a short enough sampling period is pre-selected for the system to work; (2) Only the proportional control is added until the system has a critical oscillation of the step response to the input. Make a note of the proportional amplification factor and the critical oscillation period at this time. (3) Calculate the parameters of the PID controller using the formula under a certain degree of control.