Engineer story sharing(2)

Recently, the company's colleagues designed several PLC control cabinets. Because the company considered the cost problem, it did not reserve 20% of the standby points according to the user's requirements. The number of reserved points is very small. There is only one spare digital input point in one cabinet, and the other one in the cabinet. There are only two, now the problem is coming, the field process changes, adding several electric valves, DI increased by 16 points, DO increased by 8 points, need to increase PLC modules, relays, terminals and so on. Originally, it was necessary to save costs. As a result, secondary purchases, secondary design of drawings, installation of components and wiring in the on-site cabinet, and extension of the construction period were originally intended to save money, and the result was more money.Process changes in automation engineering are very common, so some points are reserved as spare points. Many design institutes require 20% reserve. The main function of the backup point is to prevent process changes from adding equipment, and if an input input point is burned out. Change to the alternate point, my design is often a module to reserve 4 input points, such as a 32-point input module to reserve 4 spare points, which can increase the input of a device, such as the remote control of the motor / local, operation, fault, 3 input points, electric valve control has remote / local, open in place, closed in place, fault, 4 input points, 4 spare inputs reserved on each input module Suitably, it is more appropriate to reserve more than 2 output points for each module on the output module. If you consider that you reserve a 20% margin, you want to reserve less, and you should not use less than 10% of the reserved amount. In addition, you must leave enough space in the cabinet. If the site changes greatly, the reserved amount is insufficient. Add components to the cabinet.

The PLC reserved points should not be concentrated at the end of the rack. It is best to assign them to each module. If you touch a PLC point, you can find the alternate point nearby.

If the PLC cabinet design can be looser, it should be as loose as possible. The relays in the PLC control cabinet are more used. You can choose a slightly narrower relay. For example, the common combined relay width is about 25mm. Changed to about 15mm, the price is basically the same. Many designers added a cable slot under the terminal block. Personally, this is a bit redundant. The external cable is connected to the bottom of the terminal. It is inconvenient to connect the cable slot and occupy the space inside the cabinet.

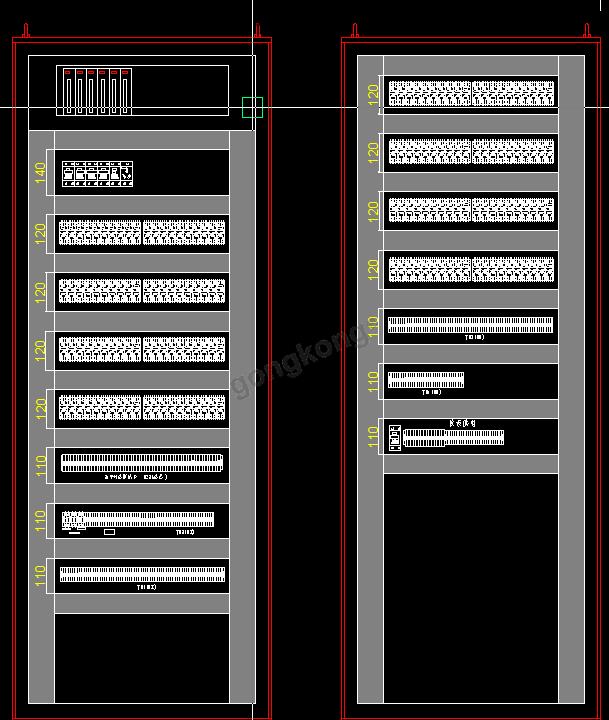

The layout inside the cabinet is designed by the company's colleagues. It can be seen that the space inside the cabinet is still quite rich. The space can be left under the mounting board. If the PLC module is to be added, the relay will be very troublesome. The whole cabinet wiring must be removed. The layout, such a reservation completely lost its meaning.

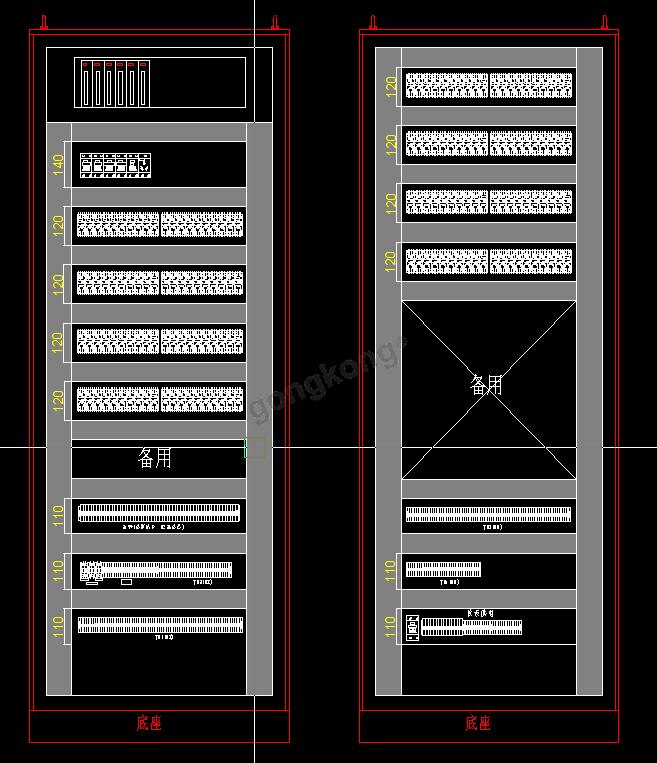

The picture below is my rough modified layout. Place the reserved space in the middle of the installation board. If you need to expand the original, you don't need to change the original layout in the cabinet.

As can be seen from the above figure, the field cable wiring must be connected to the terminals through the two side slots, which will cause the two side slots to be full, and the line is very difficult to check. The figure below distributes the external wiring into three slots by placing the terminals vertically, and the slots are less crowded.

- Previous:Engineer story sharing(1)

- Next:Engineer story sharing(3)