How is the Autonics sensor high imitation? How difficult is it to identify true and false? Disassemble the sensor evaluation!

Photoelectric sensor for comparison of true and false sensors

It is BEN5M-MFR from Autonics.

Why did you choose this sensor for evaluation?

1, because of the wide voltage range, a wide range of applications

2, the detection distance is as far as 5m

3, belonging to the economical photoelectric sensor cost-effective

4, the brand of this model photoelectric sensor online sales

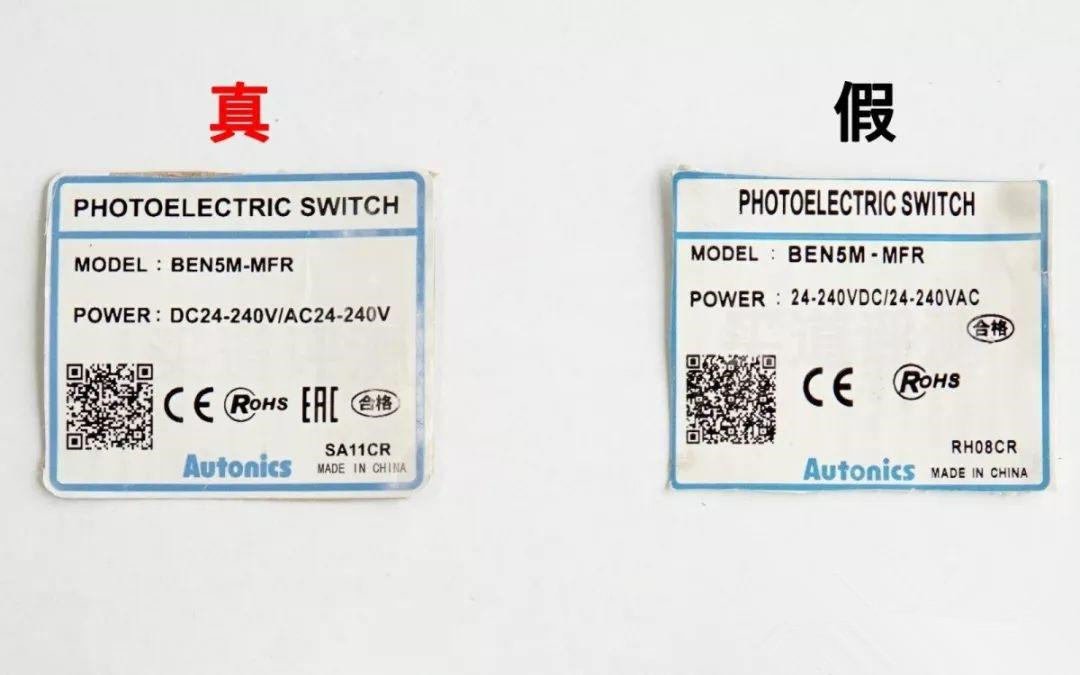

The picture above is the product label for this product.

In order to avoid interference from the box

We will uncover the label separately and take a photo comparison

Can see replicas than genuine

There is almost no difference except for the absence of an EAC logo.

"EAC certification is also the certification of the Customs Union, which is CU-TR certification. It applies to the countries of Russia, Belarus, Kazakhstan, Kyrgyzstan and Armenia (the Eurasian Economic Union of these five countries), as long as it is at the Customs If the products within the scope of the alliance's technical regulations are exported to the above five countries, they need to be certified by the Customs Union and obtain the EAC certificate, so that the products can be sold in these five countries, and the EAC logo can be pasted on the products."

If you have to find out the difference

The first line of English has a slight difference in typesetting and fonts.

It is difficult to judge if there is no genuine comparison.

Unless you are very familiar with the fonts used by Autonics LOGO

It’s hard to tell if it’s only from the appearance

The font of this point is slightly different

The picture above shows the side of the sensor (when the outlet is on the right)

Same 3C certification mark

The difference between imitation and authenticity is only a slight difference in font

The top part of the above image is the top of the sensor

Includes status lights, adjustment knobs, etc.

Please pay attention to the CE mark in the upper right corner of the product.

Genuine have imitation no

The color of the authentic and replica logo

Authentic shallow imitation deep

Genuine and replica adjustment potentiometer knob

Authentic color deep word opening imitation light cross opening

The lower part is the illuminating and receiving sensing window

Please pay attention to the lens material of genuine and replica

Genuine use of colored lenses with wavelength filtering

The replica uses a transparent material of colorless lens

The difference is the difference in resistance to light interference.

Lens with wavelength filtering

Anti-interference will be significantly higher than colorless transparent lenses

This is also the biggest difference that can be seen from the current appearance.

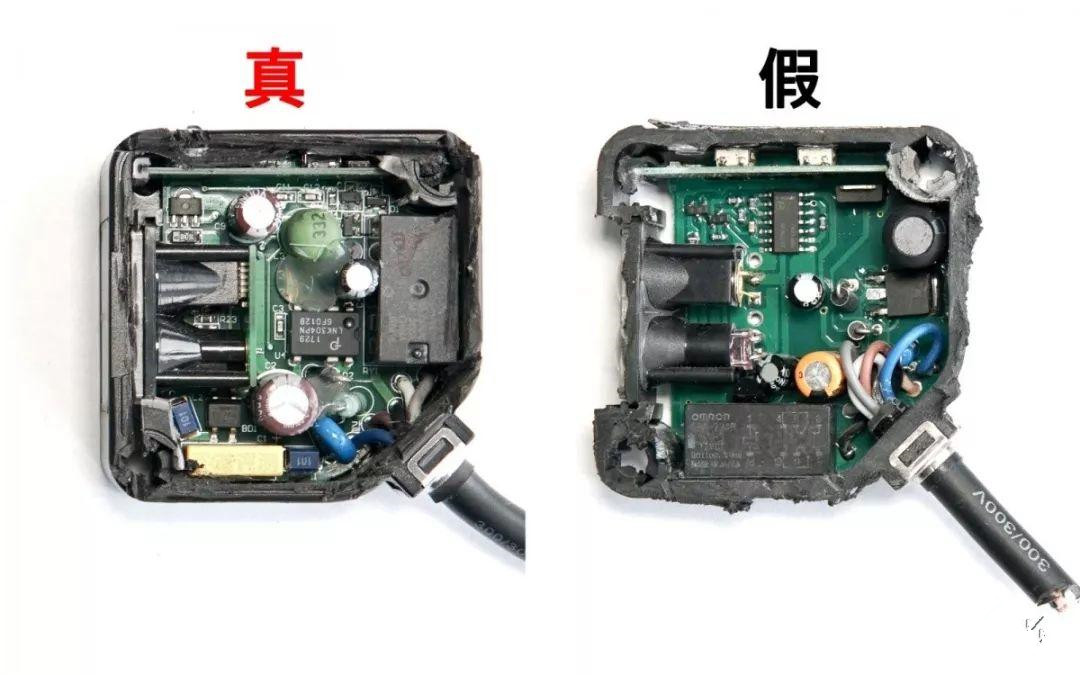

Here is how we disassemble the two sensors

See what is the difference inside

Let’s first take a look at the enlarged view of the key parts.

As a light sensor part of the optical path is definitely the focus

The genuine launch receiving part is made up of four support columns

The support column is also connected to a small flat board

The most basic guarantees the stable installation of the transmitting and receiving hardware

Basically guarantees the parallel stability of the optical path transmitting and receiving components

The replica launch and receive diodes are freely supported by the pins.

There is no fixed device, which is a bit random.

Disassemble the transmit receive window

No wonder the installation requirements of genuine components are very high.

Imitation goods can be installed at will

It turned out to be because

Genuine launch and receiving aperture diameter of about 1mm

The emission and receiving aperture of the replica is about 4mm in diameter

We can understand

The smaller the spot diameter, the higher the accuracy of the optical path.

The smaller the diameter of the measured object can be

The lower the probability of being disturbed

Let’s look at the overall internal layout.

Is it not the same as the appearance is almost indistinguishable?

Internal differences are still very large

Component selection, board layout, and processing of the optical path

A few points worth noting here

1, component selection:

Genuine components are obviously much better quality

The components of the replica have been reduced a lot.

2. Relay:

The relay used in the original is the domestic Hongfa brand

The imitation is OMRON relay

But about our understanding of Omron products

The authenticity of this relay...

3, the use of safety capacitors: the yellow part of the lower left corner of the genuine

Safety capacitors are generally anti-interference

There is no such copy in this part.

4, the welding of components:

Authentic components, each soldering is horizontal and vertical

The upright component of the replica is welded

SMD components are also twisted and twisted

I am very curious why it can be welded like this

The above is the true and false evaluation of this photoelectric switch sensor.

all content

in conclusion

As a sales volume in the market of Autonics

A model with high cost performance and versatility

The appearance of the imitation is super-hearted.

Almost difficult to distinguish from genuine

But when we opened it, we found it

The internal work gap is huge

Every detail can affect electrical performance and service life

It is difficult to buy a sensor and go back to cut it when we usually purchase it.

First of all, this can't be costed, and time can't be drawn.

Therefore, it is recommended that you still find a regular supplier, do not covet small cheap

This is an effective way to prevent false sensors in advance.